Let’s Talk Farming Series

Saskatchewan farmers rely on a vast toolkit of technologies to produce their crops every year. Farming practices are always changing, and innovation and adoption of new technologies are vital to improving agricultural efficiency, productivity, and sustainability. This is the fifth in a series of blogs that will dive into some of the important technologies used by Saskatchewan farmers and discuss the current issues surrounding them. Check out the rest of the series, where I discuss fertilizer use, pesticides, seeding, and digital ag.

What's the Scoop on Harvesting and Grain Storage?

After planting and in-crop chemical or fertilizer applications have been made, the harvest season can begin when the grain reaches maturation. However, this does not simply mean going into fields, cutting down plants, and hauling the grain to market. Crops must be prepared for grain collection either through desiccation (spraying the crop to kill any remaining plants, including weeds) or swathing (cutting the crop down and laying it in swathed rows for pickup). Once the grain is harvested, storing the grain at the correct temperature and moisture to minimize risk of spoilage is another complex task. These important, consecutive tasks make harvest one of the busiest and most labour-intensive times on Canadian grain farms.

Harvesting Technologies

For the major crops grown in Canada, harvesting can be completed by cutting down the plants in a separate pass (known as swathing) and leaving the cut crop to dry in parallel strips (or swaths) 1-2 weeks prior to gathering the grain with a combine and a pickup header. Alternatively, most crops can also be straight cut, which involves cutting and gathering the grain in the same pass, using a combine with a straight cut header attached. In most cases, the crop is desiccated (sprayed) a couple of weeks prior to harvesting to ensure that the green plant material is dried down. There are pros and cons to both the desiccation and straight cutting harvest method and the swathing and pickup method, and most farmers use a combination of the two depending on the crop type, expected yield, weather conditions, and time constraints.

Grain Drying

Each crop has specific moisture levels that indicate the grain is dry and ready for harvesting. Grain elevators will typically only accept grain that is at or below the required moisture level, which is the percentage of water present in the seed. For example, canola is considered dry at 10% moisture, while wheat is dry at 14.5% moisture. By harvesting small areas of the field and testing a sample of the grain using a moisture tester, farmers can determine if their field is ready to be harvested or if they need to let the grain dry a little while longer.

Farmers do their best to harvest crops when the moisture levels are dry enough for safe storage or hauling to the elevator, but as we’ve discussed previously in this blog series, sometimes it just isn’t possible to take off all crops at the ideal time; multiple fields might be ready for harvesting at the same time. Sometimes farmers will harvest the crop when the grain is still tough or damp (above the desired moisture level) and rely on the use of aeration fans or grain dryers to bring the moisture levels down.

Aeration fans force air through the bin-stored grain, helping to dry down grain that is slightly tough. With aeration alone, moisture levels can typically only be brought down by 1-2% depending on the aeration technology, bin size, outdoor air temperatures, and grain type. Moisture levels in oilseeds can typically be brought down more than those of cereal crops. For grain that is harvested well above the required moisture level and aeration alone cannot reduce moisture levels enough for the grain to be sold, grain dryers are sometimes used either on farm or at the grain elevator.

One issue with drying grain in Canada is that utilities that fuel grain dryers, including propane and natural gas, are not currently exempt from the carbon tax. However, the recently proposed Bill C-234, which is expected to pass a vote in the House of Commons, would expand the current carbon tax exemptions to include fuel used to dry grain on farm. Bill C-234 includes a “sunset clause”, meaning that the exemption will be revisited in eight years. Additionally, under the Federal Government’s Clean Technology Program, famers had the opportunity to apply for funding to implement greener technologies. In early 2022, 60 Canadian farms received funding, and funding for 28 more projects was announced in July. Potential projects under this program include the adoption of more efficient grain drying technology. For example, the Wendland farm near Waldheim was approved for just over $250,000 to help cover the costs of a high-efficiency grain dryer.

Storage Requirements

After harvest, grain can be stored in a variety of ways. Permanent storage structures like grain bins are commonly used on farm or at bin yards. Advantages of grain bins include ease of handling and monitoring, opportunity for aeration, and limited risk of wildlife damage or contamination. However, capital investment is required, and transport time and costs can be high if the bins are not located close to the field.

One option for temporary storage is grain bags, which are typically filled in the field as the grain is harvested and remain there until the grain is sold. Filling a grain bag in the field cuts down on transport time and costs; however, specialized bagging and extraction equipment is required. Grain bags are also more difficult to monitor and are more susceptible to wildlife and environmental damage and contamination.

Sometimes grain is stored in open piles on the ground, leaving the grain even more susceptible to damage. Farmers may choose this storage option if they will be selling the grain soon and have limited storage facilities, especially during high-yielding years.

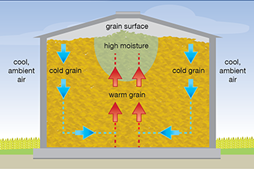

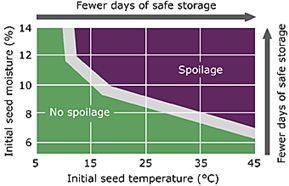

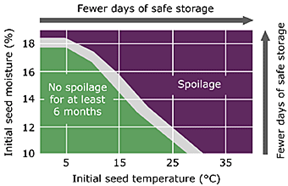

Once grain is put into storage, whether for a few weeks or months, moisture and temperature monitoring is not over. Contamination or grain spoilage from moisture, high temperatures, or pests is a devastating realization. If grain is too warm when put into bins, convection currents can develop, resulting in hotspots, moisture buildup, and potential molding or grain spoilage. Spoiled or contaminated grain results in lost dollars through either grading reductions or total loss of marketability.

It is important to know the grain temperature and moisture when it goes into storage, as this helps to determine the risk of spoilage and how many months the grain can be safely stored. Each crop has differing temperature and moisture requirements for safe storage.

Monitoring and management of grain in storage can be completed by physically checking the grain inside the bin or by using temperature sensing cables or probes. If a farmer is concerned about a lack of air movement inside a bin and they do not have access to an aeration system, they can turn the stored grain by auguring out roughly one third of the grain and then putting it back into the bin. This creates air movement and can help to cool the grain down.

What Comes Next?

Successful harvest and grain storage is an extremely important part of the crop cycle, ensuring farmers receive payment for their hard work throughout the growing season. After growing, harvesting, and storing the grain, the last thing for farmers to do is sell it. However, for most farmers, the process of selling their grain has begun long before harvest is completed through the use of marketing tools such as forward contracting and price targets. In the final blog in this series, I will discuss the many ways farmers sell their grain to receive payment for their year’s work.