400 new micro-breweries are started every year in North America

What’s in a beer?

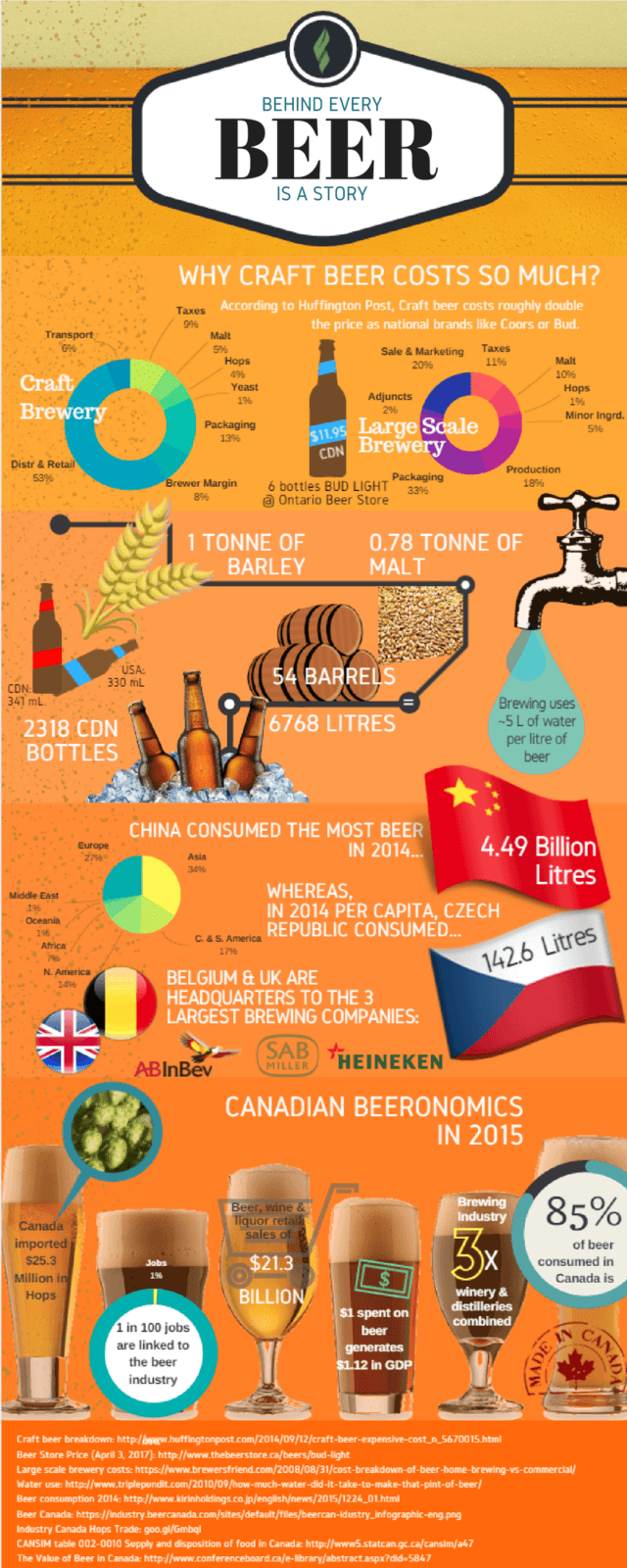

Behind every beer, there’s a great story of what it’s taken to get the product to you. Like many of our favourite foods and beverages, there’s a lot of hard work and time that goes into our beer. If you’re a homebrewer you will know about the inputs, labour and money it takes to whip up a batch of barley sandwiches, but many of us are unaware of what it takes to produce a dozen cold ones.

It all begins in the fields. Two of the four key ingredients are agriculturally produced: grains and hops. The grains are later malted and used as a starch or sugar source, while the hops provide a bitterness, it also stabilizes and preserves the beer. These two key ingredients of bitter and sweet not only require time and inputs to be grown, they also require further processing before they become beer ingredients.

Growing beer

The first step in brewing beer is to obtain a malting grain, most often barley is used. What is malt? Simply put, it’s the preservation of grain by drying. While our explanation is short and simple, malting isn’t! For the ever growing and innovating malting industry, the process needs to be efficient, while maintaining quality and meeting demand. For the simplicity, we’ll say malting has three key steps. First, it must be steeped, which allows the grain to absorb moisture. It then begins to sprout and germinate, this process takes a number of days. Once the desired moisture and maturity is reached, the germination is halted by drying the grain. Through drying the sugars and starches are preserved prior to milling the malt. It is important to preserve these sugars, as they facilitate fermentation as well as providing colour and flavour.

Hops flowers are harvested from a perennial vine in late summer-early fall. The flower, which looks like a leafy pine cone, is dried in a kiln. Once dried, they’re processed into bales, pellets, powder or extracts for future processing purposes.

Beer is practically water

Beer is practically water

Life cannot exist without water, neither can beer. In fact, water makes up roughly 90-95% of beer, therefore quality water is important. Some breweries rely on a clean and pure quality water, while others will filter their water before brewing. Anheuser-Busch uses multistage filtration to reach a standard quality, providing consistency for their beer.

Next, a mash is made by mixing the milled malt and hot water. After a few hours, the malt starches turn into sugar and the mixture becomes a ‘sweet wort’. The wort is then poured off the grain and into a kettle ( a.k.a Copper) for boiling, where the water evaporates and hops are added. The hops wort is cooled and the last key element of beer, yeast, is added. The yeast ferments the wort and hops, creating alcohol. Depending on the type of beer, fermentation can be anywhere from a week to a month (or longer for a good lager).

After fermentation, the beer is either bottled, casked, kegged or canned. From packaging, the product is stable to be transported and sold to warehouses, eventually to be sold to you and me.

In every bottle and behind every label is a story of hard work and pride in the quality of inputs and production. Cheers to the farmers, maltsters and brewers who work so hard to bring us the joy of a cold brewed beer!