The losses associated with the rise in chemical spray drift in agricultural landscapes

By: Royce Moellenbeck

University of Saskatchewan student

The Cause of Spray Drift

The agriculture industry in Western Canada has made significant impact over the years to grow high quality crops and higher yields with the limited land that is available. Technological advancements in plant breeding have bred plants that are tolerant to certain speciality crafted chemicals that combat competitive weeds, diseases, and harmful pests. The application of these chemicals has been done through mixing water with the chemical concentrate and spraying it on the field.

Spraying equipment began with small working areas of 10ft, then moved to pull type sprayers covering 50ft. The creation of the self-propelled sprayer with high clearance allowed spraying to become quicker. These high clearance self-propelled sprayers now have increased their boom size to over 120ft. While great improvements have been made in tracking what areas of the field have had application through precision agriculture, weather conditions and differences in the abilities of operators have not changed.

Weather conditions play a massive role in the spraying operation for farmers. Too much wind and the chemical they are spraying will drift away from the area they want it. When it is too calm the chemical may just hang in the air and slowly drift from its prescribed location. Foggy conditions will hold chemical in the air due to its small particle size of water and will disperse the chemical away from its first location when it came out of the sprayer. Humidity and air temperature also can affect spray drift.

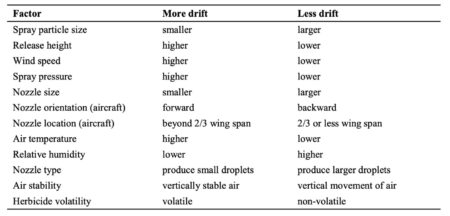

Particle size and nozzle shape are one way that farmers can avoid causing spray drift. Adjusting for small droplet and particle size in a pan shape is the best way to cover the entire crop. However this is also the perfect recipe for allowing more spray drift. Each of the factors affecting spray drift and their consequences to spray drift can be seen in Table 1.

How to avoid it

Lower spray nozzle height, lower pressure and increase nozzle size are common things farmers can do to most common spraying equipment. Updates in nozzle design have made great improvements to reducing spray drift. These new nozzles utilize a pressure-reducing chamber, creating a larger droplet size while maintaining the flow rate and pressure of a comparable flat fan nozzle. Common names of these nozzles are DriftGuard, TurboDrop, Air Induction TeeJet, Turbo TeeJet, and Turbo Flood.

While nozzles are one way to decrease spray drift, sprayer shields also help decrease spray drift. These shields can cover the full length of the boom and will usually reduce drift by 50% or more compared to an unshielded sprayer with the same nozzles. Individual nozzle shields are also an effective way of preventing spray drift.

Aerial Application

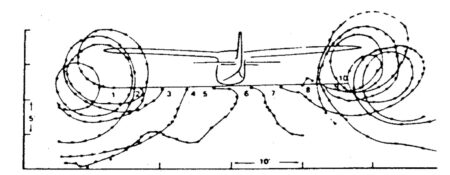

Aircrafts spraying chemicals for farmers have grown in the past number of years. Because of the planes’ design and movement speeds across a field, irregular air drifts around the wings are formed. Shown in Figure 2, aircrafts can create many different forces of air so location of nozzles on booms, spacing of nozzles, and length of boom are very important.

Aerial application is popular for when crops are at a later stage, commonly for fungicide application and desiccation for harvesting. By using planes, farmers can avoid losses in their field from driving over crop and shorten the amount of time it takes to spray due to travel speed. The ability to spray when ground conditions are too wet for a ground sprayer is also a major advantage. Spray drift of fungicide is not as evident and consequential as desiccants due to it not being a herbicide. However, labels of certain products require a ground sprayer to do the headlands as a buffer zone.

Consequences of Spray Drift

On three separate occasions, my family has experienced the results of spray drift from desiccants. One occasion was the first 500ft of our pasture alongside a canola field was burned off. This was a major setback as the grasses died and allowed for weed population to increase very quickly. Another occasion which is common across the prairies is road ditch’s being sprayed out. The consequences of this are the weeds take over control of the ditch due to the grass dying so it is just a breeding ground of more weeds as well as increasing ditch erosion, harming the integrity of the gravel roads. The third occasion was aerial application by a hired company who sprayed during improper weather conditions and caused spray drift to travel over 1 mile. Three family farmyards all reported chemical spray in their gardens where fresh produce that was ready to pick such as cucumbers, peppers and cabbage had to be discarded.

What Can be Done?

Currently the Government of Saskatchewan and the Ministry of Agriculture do not require a Pesticide Applicator Licence for producers who spray pesticides on their own operation. With farm sizes increasing, producers are beginning to purchase their own aircrafts. Because of this more steps need to be taken to ensure people applying chemicals via aircraft are well trained in flying during recommended spraying conditions.

The situation of desiccant spray drift is a conversation that needs to continue. While desiccants play an important role of finishing harvest in a timely manner while still putting a high quality and high yielding crop in the bin, the consequence of drift is impacting the rest of the prairie landscape. Possible solutions could include banning aerial desiccant application or requiring low drift nozzles and/or nozzle shields. While spray drift is something that farmers do not plan for, it is an action that has irreversible effects and needs to be taken seriously.

Biography

My name is Royce Moellenbeck, I am completing my final year of study at the University of Saskatchewan with a Bachelor of Science in Agriculture, majoring in Animal Science, and pursuing a minor in Agricultural Business. I grew up on my family’s grain and livestock farm outside of Englefeld, Saskatchewan. Agriculture has always been a passion of mine and is an industry that I am excited to enter. I look forward to using the tools I have learned from growing up, working at my summer jobs and from my post-secondary education to help make a postive, progressive impact in the agriculture industry.

My name is Royce Moellenbeck, I am completing my final year of study at the University of Saskatchewan with a Bachelor of Science in Agriculture, majoring in Animal Science, and pursuing a minor in Agricultural Business. I grew up on my family’s grain and livestock farm outside of Englefeld, Saskatchewan. Agriculture has always been a passion of mine and is an industry that I am excited to enter. I look forward to using the tools I have learned from growing up, working at my summer jobs and from my post-secondary education to help make a postive, progressive impact in the agriculture industry.