By Justin Harcourt

University of Saskatchewan student

As a fourth-generation rancher, I have always been interested in the business side of the cattle industry. It has always intrigued me how an industry filled with so many passionate and educated producers struggles to increase its margins. Low stress management practices are something that the Canadian Food Inspection Agency (CFIA) guidelines for humane care and handling of food animals outline but do not incentivize; and that’s the issue.

CFIA Guidelines

CFIA defines humane handling as a method of handling and slaughter practices that cause a minimum of excitement, pain, injury, or discomfort the outcome being to prevent avoidable suffering to the food animal. There are specific guidelines related to transport and scheduled delivery times to reduce stress on animals being trucked any distance. Unloading of most animals should be within a half hour of arrival and completed within an hour to avoid the impact of heat stress during the warm seasons. These guidelines promote low-stress cattle handling after unloading under their humane handling regulations.

What Do We Consider Stress?

Dr. Temple Grandin, a world renown professor at Colorado State University has dedicated her life to designing safe livestock handling facilities. Her methods have been implemented globally and is based on the research of cattle behaviour, their flight zones, the principles of grazing animal behaviour have helped many people to reduce stress on their animals while handling. According to Grandin, the degree of stress is determined by three major factors — 1) amount of contact with people, 2) quality of handling (rough vs. gentle) and 3) genetics. Frequent, gentle handling will reduce stress.

Low Stress Cattle Handling – Facilities

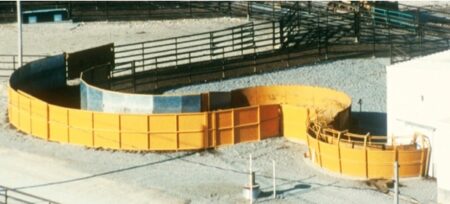

The “Serpentine Ramp” is one example of Temple’s work. It embodies the handling facility layout rules. These systems and rules are to utilize the ‘herd mentality’ which keeps the cattle together and calm. You’ll see the many curves in this system, this is because as the cows turn, they think they are going back to where they came from. Not every system and operation will be able to afford extensive systems as the one shown above. They can, however, implement their own systems following the same principles of moving cattle and handling facility layouts that Temple and other researchers have introduced to the cattle industry.

The “Serpentine Ramp” is one example of Temple’s work. It embodies the handling facility layout rules. These systems and rules are to utilize the ‘herd mentality’ which keeps the cattle together and calm. You’ll see the many curves in this system, this is because as the cows turn, they think they are going back to where they came from. Not every system and operation will be able to afford extensive systems as the one shown above. They can, however, implement their own systems following the same principles of moving cattle and handling facility layouts that Temple and other researchers have introduced to the cattle industry.

Low Stress Cattle Handling – Cheap & Effective Options

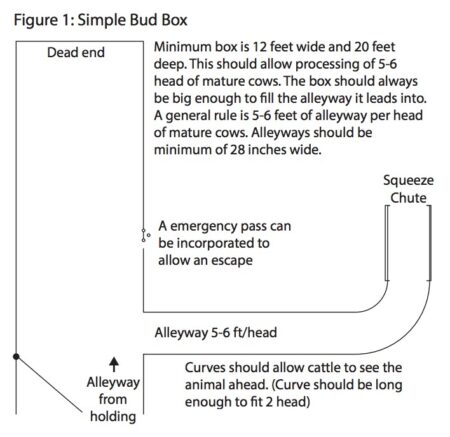

(Source: Kansas State University)

The Bud Box. If you have cattle, odds are you have at least heard of this system before. Designed by the late Bud Williams, the founder and instructor of low-stress stock handling techniques, the Bud Box is essentially a rectangular pen with a chute entrance placed at a right angle close to the point of entry into the box. Cattle will push all the way to the front of the box, turn back towards where they entered when they realize it is a dead end and smoothly go into the chute as they see it as a way to exit (Figure 1).

An additional option for chutes is anti-backing bars that can be set to any height necessary to prevent cattle from backing up into each other which saves time for handlers and prevents bruising in carcasses (Figure 2).

Increased Carcass Quality

Bruising is frequently a large problem in extensively reared cattle unused to handling. Bruised tissue is trimmed, reducing yield as well as often leading to downgrading. Low stress cattle handling prevents bruising. By preventing this, it directly improves/maintains the carcass integrity and quality. This helps the Canadian beef industry supply the highest quality product to consumers both foreign and domestic. It’s easier on the animal, the handlers, improves meat grade, profitability for both local producers and corporate meat suppliers; but how does any of this relate to policy?

Why Make it Policy?

Current government programs such as Verified Beef Plus (VBP+) are amazing for providing producers access to funding for new facilities, grazing management systems, equipment and even buildings. This program is geared towards encouraging sustainable practice among producers. I am proposing a policy change or the beginning of a program that strictly funds or incentivizes producers to review their handling systems and if they qualify as low stress when looking at the practices that visionaries such as Bud Williams and Temple Grandin have promoted. Producers are able to use VBP+ as they see fit for their operation, this new program would be solely for handling equipment as this has direct effect on beef quality. Feedlot and slaughterhouse facilities also need to be maintained in accordance to low stress management. This is proven to be best for the cattle, the handlers, the beef supply chain and consumers of Canadian beef worldwide.

Biography

My name is Justin Harcourt and I am a 4th year Bachelor of Science in Agribusiness student at the University of Saskatchewan. I am from Quill Lake, SK where my family owns and operates Harcourt Charolais, selling purebred Charolais bulls, females and frozen genetics across Canada and the United States. I plan to stay involved in agriculture and advocate for the sustainability, integrity and adaptability of the Canadian Beef industry.